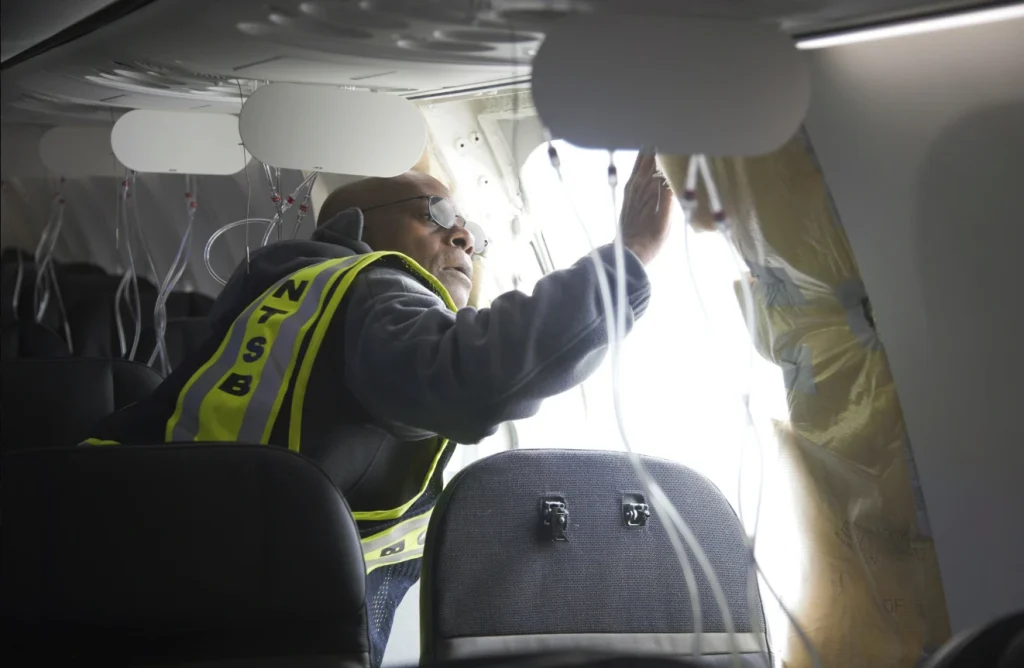

The recent blowout of part of the fuselage on a Boeing 737 Max flying over Oregon has once again brought to light the safety issues plaguing the aerospace giant.

This incident adds to a series of problems, including two devastating crashes, that have raised concerns about the safety and reliability of Boeing aircraft.

The 737 Max, the latest iteration of the long-standing 737 model, has been at the center of the most serious issues faced by Boeing in recent years.

United Airlines’ revelation of loose bolts and other installation issues discovered during inspections of other 737 Max jets following the mid-air blowout on an Alaska Airlines flight further underscores the extent of the problems affecting this aircraft.

In 2018, a tragic incident involving a Southwest Airlines 737 resulted in the death of a passenger when a piece of engine housing tore off, causing a window to shatter and leading to a partial ejection of the passenger due to loss of cabin pressure.

This harrowing event serves as a stark reminder of the potential dangers associated with aircraft malfunctions.

Boeing’s troubles with the 737 Max began in 2011 when the company embarked on its development as a response to a more fuel-efficient model introduced by European competitor Airbus.

Marketed as an updated 737 requiring minimal additional pilot training, the Max incorporated significant changes, including an automated flight-control system called MCAS designed to accommodate the plane’s larger engines.

Notably, Boeing did not explicitly disclose the existence of the MCAS system in airplane manuals, leaving many pilots unaware of its presence.

Tragically, the MCAS system was implicated in two fatal crashes that claimed the lives of 346 individuals. The first crash involved a Max 8 operated by Indonesia’s Lion Air, which plunged into the Java Sea in October 2018.

The second crash occurred when an Ethiopian Airlines 737 Max 8 went down shortly after takeoff from Addis Ababa.

These catastrophic events prompted a global grounding of all Max jets for nearly two years while Boeing undertook modifications to the flight-control system.

In the wake of these tragedies, Boeing faced intense scrutiny and legal challenges. The company agreed to a $2.5 billion settlement with the U.S.

Justice Department, acknowledging that its employees had misled regulators regarding the safety of the 737 Max. This settlement included a $500 million fund for the victims’ families, although legal actions against Boeing persist.

The investigations into the 737 Max crashes revealed a troubling combination of regulatory oversight failures, design flaws, and inaction within Boeing.

A congressional panel described the situation as a “horrific culmination” of these systemic issues, underscoring the gravity of the lapses that contributed to the tragedies.

In conclusion, Boeing’s recent history has been marred by a series of safety concerns and operational challenges, particularly with the 737 Max.

The incidents and subsequent investigations have highlighted the critical need for rigorous safety protocols, transparent communication, and effective regulatory oversight within the aerospace industry.

As Boeing continues to address these issues and work towards restoring trust and confidence in its aircraft, the broader aviation community must remain vigilant in prioritizing safety and accountability to prevent future tragedies.

The Boeing 737 Max has faced a multitude of issues in its production, raising concerns about the safety and reliability of the aircraft.

These recent incidents have brought to light various problems that have plagued the Max, prompting Boeing and the Federal Aviation Administration (FAA) to take action to address these issues.

One of the most concerning issues is the potential loose bolt in the rudder control system. This was brought to the attention of airlines after an international operator discovered a bolt with a missing nut during routine maintenance.

In addition, an undelivered aircraft was found to have a nut that was not properly tightened. These findings raise serious questions about the quality control and manufacturing processes at Boeing and its suppliers.

Furthermore, the FAA has advised pilots to limit the use of an anti-ice system on the Max due to the risk of engine inlets overheating and breaking away.

Boeing has requested a safety waiver from the agency while it develops a long-term solution to this problem. This indicates that there are fundamental design and engineering flaws that need to be addressed in the Max aircraft.

In a separate incident, Boeing reported a problem with fittings on Max jets where the fuselage meets the vertical section of the tail.

The company attributed this issue to a “non-standard manufacturing process” used by its supplier, Spirit AeroSystems.

This raises concerns about the oversight and quality control of Boeing’s supply chain, which is crucial for ensuring the safety and reliability of its aircraft.

These series of production issues have not only raised concerns about the safety of the Max, but also have significant implications for Boeing’s reputation and financial performance.

The company has been under scrutiny for its handling of the Max crisis, and these new problems only add to the growing list of challenges it faces.

In conclusion, the Max’s production issues highlight the need for greater oversight and accountability in the aerospace industry.

It is imperative that Boeing and its suppliers take proactive measures to address these issues and ensure the safety and reliability of their aircraft.

The FAA must also play a critical role in enforcing strict regulations and standards to prevent such incidents from occurring in the future. The stakes are high, and the industry must work together to restore confidence in the safety of air travel.

Boeing, a renowned aerospace company, has recently faced a series of challenges related to manufacturing issues in its aircraft.

These issues have raised concerns about the safety and reliability of Boeing’s planes, leading to delays in deliveries and investigations by federal safety officials.

This essay will delve into the specific incidents involving the 737 Max and 787 models, as well as the implications for Boeing and the aviation industry as a whole.

One of the key issues that have come to light is the discovery of improperly drilled fastener holes in the aft pressure bulkhead of some models of the 737 Max.

The aft pressure bulkhead is crucial for maintaining pressure when planes are at cruising altitude, and the presence of flaws in this component has raised concerns about the safety of the aircraft.

While Boeing has assured that the flaws do not pose an immediate hazard to the planes already in operation, they have acknowledged that it could lead to delays in the delivery of new jets.

Additionally, Spirit, a key partner with Boeing on the 737 program, has been involved in addressing these manufacturing defects, particularly in the installation of door plugs in the 737 Max 9.

Furthermore, the incident involving an engine fire on a United Airlines Boeing 737 Max in Newark, New Jersey, has added to the scrutiny of the aircraft’s safety.

The discovery of a fuel leak, soot, and heat damage following the fire has prompted federal safety officials to investigate the root cause of the incident.

Similarly, the emergency landing of a Denver-bound United Airlines flight in Wichita, Kansas, due to an engine fire has raised concerns about the reliability of the 737 Max.

In response to these incidents, Boeing has reiterated its commitment to safety and expressed regret for the impact on its customers and passengers.

The company has provided technical support to assist the National Transportation Safety Board (NTSB) in its investigations.

However, the recurrence of manufacturing issues and safety concerns has put Boeing under increased scrutiny, necessitating a thorough review of its manufacturing processes and quality control measures.

The recent incidents involving the 737 Max are reminiscent of previous safety issues faced by Boeing. The Southwest Airlines flight in 2011, where a chunk of the plane’s roof opened at high altitude, resulting in a lack of oxygen and injuries to passengers and crew, highlights the critical importance of maintaining high manufacturing standards and rigorous quality control.

The NTSB’s findings of “extremely poor manufacturing technique” in that incident underscore the long-standing implications of manufacturing defects in aviation safety.

In addition to the challenges with the 737 Max, Boeing’s two-aisle 787 has also encountered manufacturing problems, leading to delays in deliveries.

The inspection of fittings on the horizontal stabilizer for a nonconforming condition and the halt in 787 deliveries while federal regulators reviewed documentation of work on new planes have raised concerns about the overall manufacturing processes at Boeing.

The series of manufacturing issues faced by Boeing in its 737 Max and 787 models have significant implications for the company and the aviation industry.

The need for stringent quality control measures, thorough inspections, and adherence to manufacturing standards is paramount to ensure the safety and reliability of aircraft.

Boeing’s commitment to addressing these issues and working with regulatory authorities is essential in restoring confidence in its products.

In conclusion, the recent incidents involving manufacturing defects in Boeing’s aircraft highlight the critical importance of upholding high standards in aerospace manufacturing.

The collaboration between Boeing, its partners, and regulatory authorities is essential in addressing these challenges and ensuring the safety of air travel.

Moving forward, a comprehensive review of manufacturing processes and quality control measures is imperative to prevent similar incidents and uphold the highest standards of safety and reliability in aviation.

In conclusion, the recent incidents involving manufacturing defects in Boeing’s aircraft highlight the critical importance of upholding high standards in aerospace manufacturing.

The collaboration between Boeing, its partners, and regulatory authorities is essential in addressing these challenges and ensuring the safety of air travel.

Moving forward, a comprehensive review of manufacturing processes and quality control measures is imperative to prevent similar incidents and uphold the highest standards of safety and reliability in aviation.